This development has significant implications for the construction sector and the real estate market. The ability to create materials that are both exceptionally durable and lightweight could lead to buildings with increased resistance to natural disasters, reduced construction weight, and improved energy efficiency. Moreover, the use of 3D printing enables the precise construction of complex structures, minimizing material waste and production costs.

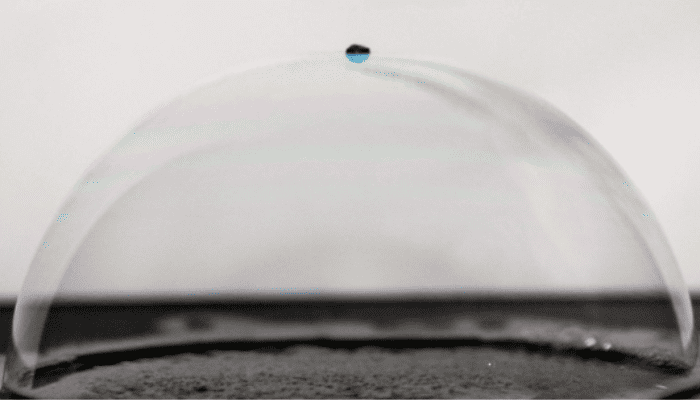

Nano-architectural materials consist of microscopic, repeating units measuring only a few hundred nanometers. To reach the thickness of a human hair, over 100 such units would need to be aligned. These units, primarily made from carbon, form intricate three-dimensional structures known as nanomeshes.

According to researcher Peter Serles, “Nano-architectural materials combine high-performance shapes, like the construction of a bridge using triangles, at the nanoscale, exploiting the 'smaller is stronger' phenomenon to achieve some of the highest strength-to-weight and stiffness-to-weight ratios of any material.”

The team collaborated with the Korea Advanced Institute of Science & Technology (KAIST) in South Korea to develop these materials. They used a machine learning algorithm to predict the optimal shapes that would enhance the strength and lightness of the materials. Serles then employed a two-photon polymerization 3D printer to create prototypes at micro- and nanoscale. The enhanced nanomeshes doubled the strength of previous models, withstanding pressure of 2.03 megapascals per cubic meter per kilogram—roughly five times more than titanium.

Incorporating these materials into constructions could also lead to new architectural forms and designs, enabling the realization of innovative ideas that were previously impossible due to the limitations of traditional materials. For example, lightweight and durable structures can be used to create large open spaces without the need for heavy supports, allowing for more flexible and open layouts.

Additionally, the use of nano-architectural materials can contribute to the sustainability of buildings. Their lightweight nature reduces energy consumption during transportation and installation, while their durability ensures longer-lasting constructions, decreasing the need for maintenance and replacement. This could result in a significant reduction in the environmental footprint of buildings.

Despite these promising advancements, challenges remain before the widespread adoption of nano-architectural materials in the construction sector. Large-scale production, reliability, durability under real-world conditions, and production costs are issues that require further research and development.

Overall, the development of nano-architectural materials represents a major breakthrough in construction technology. As research progresses and technologies improve, it is likely that we will see these materials increasingly integrated into modern buildings, fundamentally transforming how we design and construct the built environment.