The Italy-based 3D printer manufacturer WASP has joined hands with UNDP (United Nations Development Program) to deploy 3D printing solutions for the Columbian construction industry.

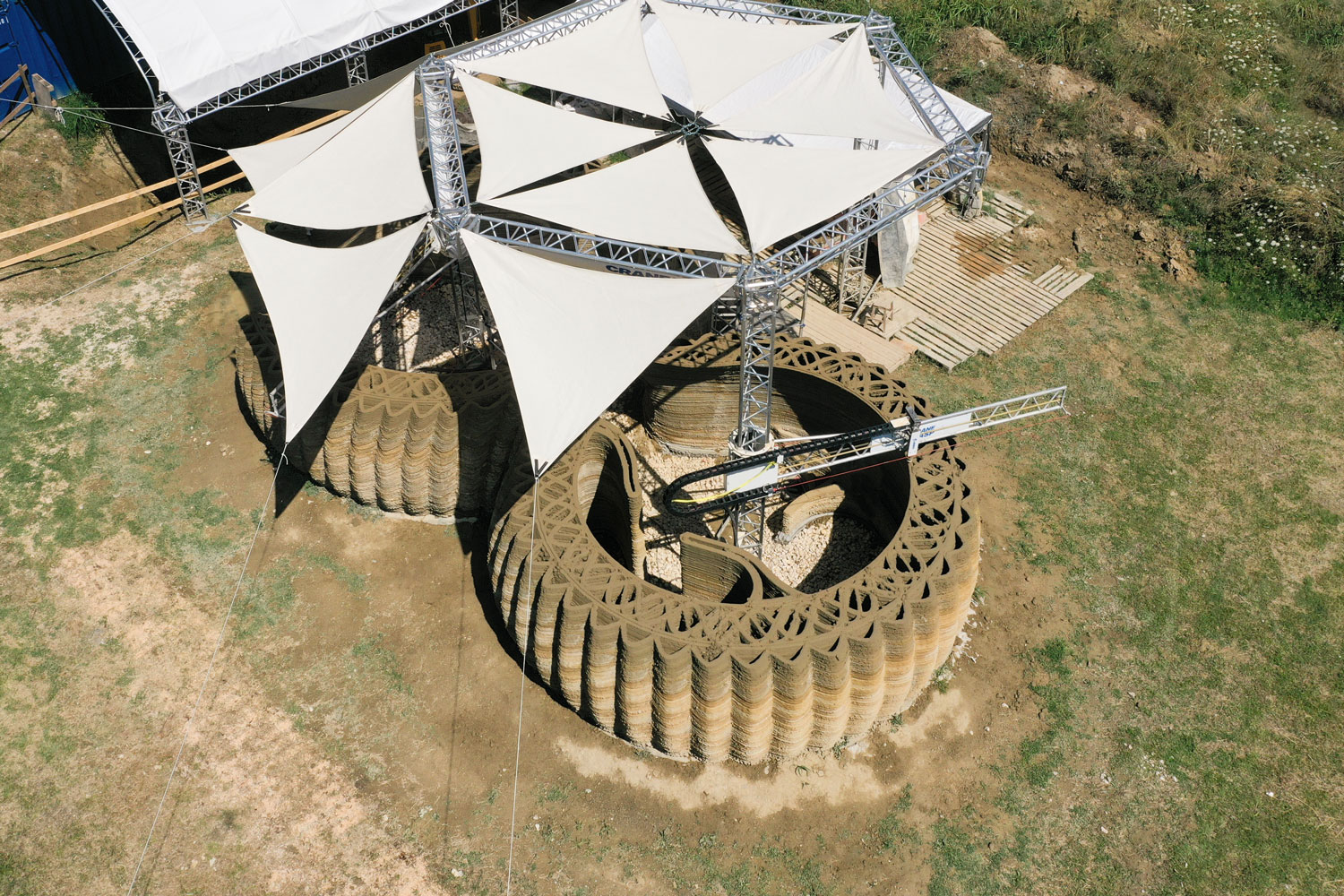

UNDP will rely on the Crane WASP for its construction projects, an architectural 3D printer that can visualize & print from local soil & natural materials like agricultural residues. This technology can be supportive in constructing buildings & other sheltering services for Colombian residents using locally made components & materials.

Crane WASP was launched in 2012. Inspired by the Potter Wasp, WASP aimed to create a large-scale 3D printer for constructing houses with naturally available components & materials within the territory.

The core strength of Crane WASP is its diverse versatility & enhanced mobility, enabling them to access challenging locations where stationary systems cannot reach that easily. The primary features like less energy consumption & seamless installation have made it possible to implement them in remote areas & even in desert regions.

This 3D printer has already been used in several construction projects worldwide including the Dropcity project/even the 23rd Triennale Milano International Exhibition.

As a reminder, the underlying benefit of construction 3D printing is its digitization process. Digital building production enables quick knowledge transfer & gaining hands-on experience during research via digital access to its inventories. After uploading these files to the 3D printer, the project is created & can be replicated infinitely worldwide even in areas of various productive capacities.

This modern approach offers the global dissemination of construction solutions, surpassing demographic restrictions & expanding development access to alternative construction solutions.

(source:3dadept)